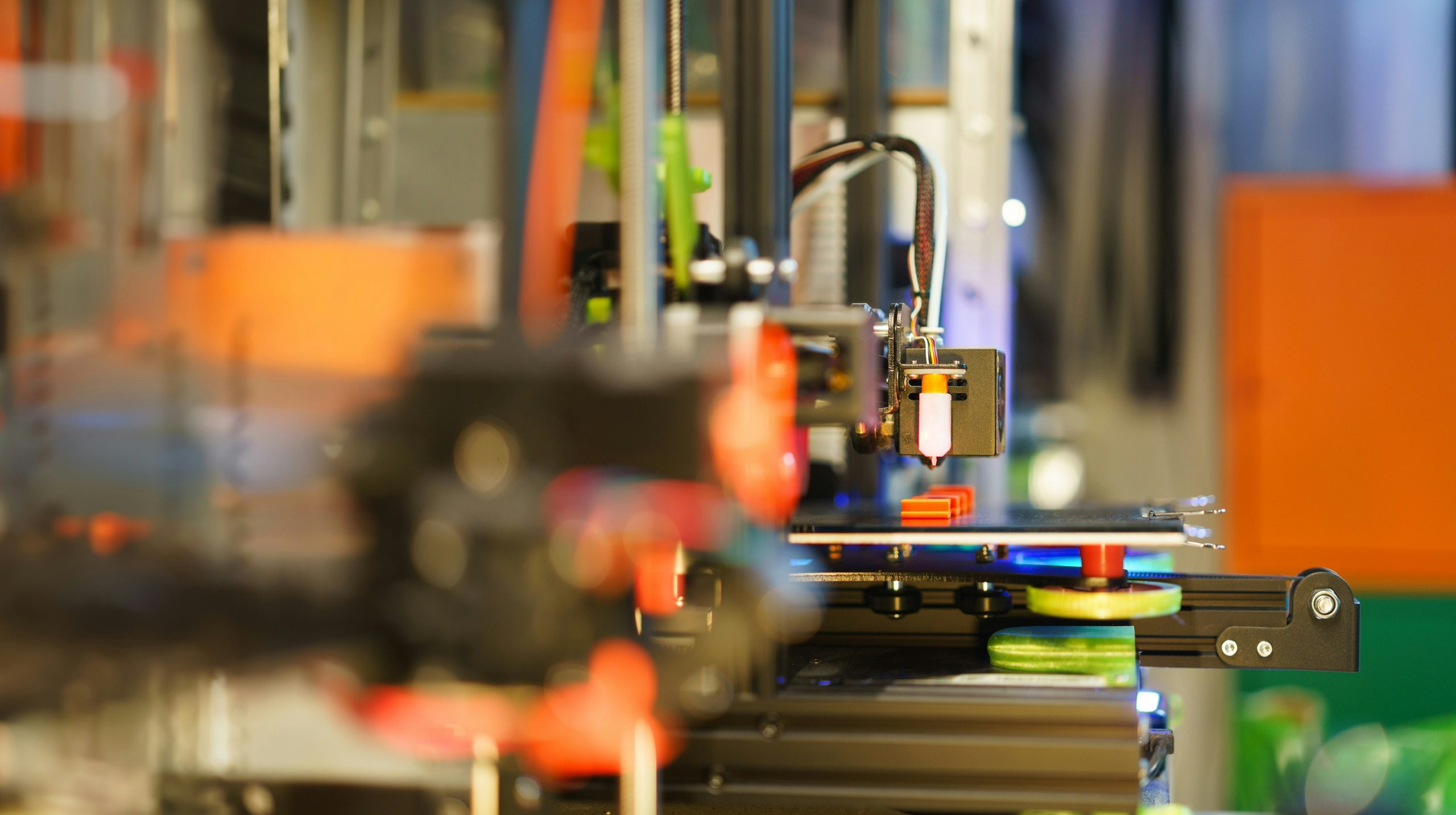

Exploring the Capabilities of Modern 3D Printing Technology

In recent years, 3D printing technology has rapidly evolved and revolutionized the way objects are created. While it was once limited to creating simple and small-scale prototypes, modern 3D printing technology has expanded its capabilities to produce complex and functional objects. With the advancement of this technology, the possibilities seem endless. Let’s delve into exploring the capabilities of modern 3D printing technology and how it is changing the manufacturing industry.

The Basics of 3D Printing Technology

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. It involves the layer-by-layer deposition of material, often in the form of a liquid resin or powdered material, that is heated and bound together to create the desired object. This method of production is known for its efficiency, precision, and ability to create highly complex structures.

The Advancements of Modern 3D Printing Technology

Initially, 3D printing was primarily used for rapid prototyping, allowing designers and engineers to quickly create physical models of their designs. However, with the introduction of new materials, improved printers, and increased print speed, 3D printing has taken on a whole new level of capability.

One of the most significant advancements in modern 3D printing technology is its compatibility with a wide range of materials. In the past, 3D printing was limited to materials such as plastic, metal, and resin. Today, we see the use of biodegradable materials, ceramics, food, and even living cells in 3D printing. This opens up a whole new world of possibilities, from creating sustainable products to producing custom-made medical implants.

The Impact on Manufacturing

The evolution of 3D printing has had a profound impact on the manufacturing industry. Traditionally, the manufacturing process involved creating a mold or prototype before mass production. With 3D printing, this time-consuming step is eliminated, leading to faster production times, reduced costs, and the ability to produce customized products. 3D printing has also allowed for the creation of intricate and complex geometries that were previously impossible to produce with traditional manufacturing methods.

Exploring Creative Possibilities

Aside from its practical applications, 3D printing has also opened up new opportunities for creativity and self-expression. Artists and designers can now bring their ideas to life with this technology, creating unique and one-of-a-kind pieces that were once considered impossible. This has also led to the rise of small businesses and entrepreneurs utilizing 3D printing for customized products and designs.

The Future of 3D Printing

The capabilities of 3D printing technology continue to expand as research and development in this field progresses. Some experts even predict that, in the near future, 3D printing will be able to produce fully functional organs for medical transplants, revolutionizing the healthcare industry. Additionally, 3D printing is also paving the way for sustainable production, reducing waste and environmental impact.

Conclusion

With its ever-evolving capabilities, 3D printing technology has proven to be a game-changer in many industries. Its potential for customization, efficiency, and cost-effectiveness is paving the way for revolutionary changes in manufacturing, art, and healthcare. As we continue to explore the possibilities of modern 3D printing, the only limit seems to be our imagination.